Software

Why Choose Our CNC Machining Services

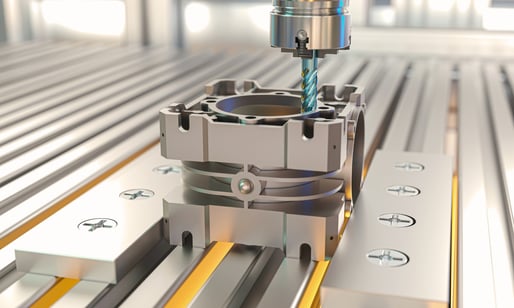

SWARCO McCain’s CNC machining operation services deliver precise, repeatable, and efficient results across every production run. We support projects of all sizes and offer secondary finishing options, all under one roof. Customers rely on us for tight-tolerance components that meet quality standards, produced within a controlled nearshore environment that reduces lead times and total cost.

Key Capabilities

Our CNC machining capabilities span high-volume production and complex precision parts with tight tolerances. With advanced multi-axis machinery, automated tooling, and skilled operators, we deliver components that meet the most demanding performance standards. Whether it’s short-run production or full-scale manufacturing, our team ensures every part is machined with consistency and confidence.

- Precision CNC machining and milling using advanced vertical and horizontal machining centers

- Turning, drilling, and threading operations for complex geometries and custom assemblies

- Multi-axis machining for enhanced part accuracy and minimized secondary operations

- We support any size production run with fast setup and changeover times

- Custom-machined parts tailored to specific material, tolerance, and design requirements

- In-house tooling and fixture design to optimize part accuracy and manufacturing efficiency

- Integrated finishing options, including powder coating and assembly for ready-to-install components

- ISO 9001:2015-certified processes with rigorous quality checks at every stage

Learn How Much You Could Be Saving Every Month. Get Your Quote.

CNC Machining FAQs

What is CNC machining?

CNC machining is a computer-controlled manufacturing process that uses programmed equipment to remove material and shape parts with high accuracy. The method ensures consistent quality, tight tolerances, and repeatable performance across large production runs.

How does CNC machining work?

The process begins with CAD modeling and CAM programming to create precise tool paths for automated machines. Multi-axis systems then cut, drill, or mill raw materials into finished parts. Each step is controlled digitally to maintain consistency and efficiency.

What materials can be machined?

We machine a wide range of materials, including aluminum, stainless steel, brass, copper, and engineered plastics. Each material is selected based on part requirements, ensuring strength, machinability, and long-term durability.

What industries benefit most from CNC machining?

CNC machining supports industries such as transportation, electronics, aerospace, defense, energy, and industrial automation. Our precision components are used in enclosures, brackets, housings, and assemblies where reliability and performance matter most.

What makes SWARCO McCain’s CNC machining services different?

SWARCO McCain combines advanced multi-axis machinery, automated tooling, and skilled operators to deliver precision parts. Our ISO 9001:2015-certified processes and nearshore facility ensure quality, speed, and cost efficiency.

Does SWARCO McCain offer production scaling?

How does SWARCO McCain ensure quality control?

How do SWARCO McCain's CNC machining services support nearshore manufacturing?

Why choose contract CNC machining with SWARCO McCain?

SWARCO McCain, Inc. reserves the right to change product specifications without notice. For the most up-to-date information, please contact SWARCO McCain.